The 25-Second Trick For Premier Aluminum Llc

The 25-Second Trick For Premier Aluminum Llc

Blog Article

Premier Aluminum Llc Fundamentals Explained

Table of ContentsFascination About Premier Aluminum LlcSee This Report about Premier Aluminum LlcThe Main Principles Of Premier Aluminum Llc How Premier Aluminum Llc can Save You Time, Stress, and Money.The Buzz on Premier Aluminum Llc

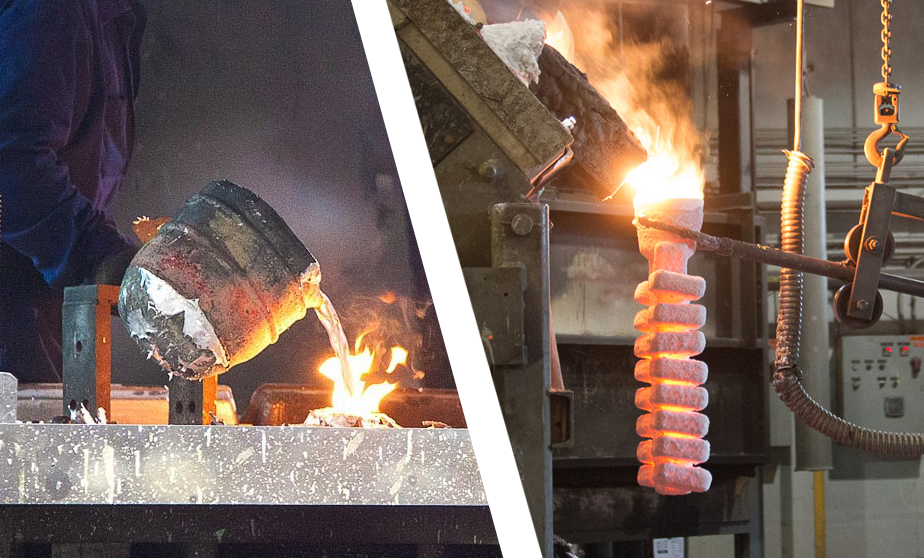

Once the casting process is full the light weight aluminum castings rapidly create an exterior layer of alumina that helps safeguard against rust. Aluminum casting processes are described as Ingot spreading or Mould casting.

The second process is used within the shops for producing cast products. Foundry. This is frequently the oldest and simplest (in theory yet not in technique) indicates of generating designed components. This area defines exclusively Mould spreading which may be divided right into two main teams: Other techniques like "lost foam" or "wax pattern" procedures additionally are utilized but their affordable relevance is significantly much less than both listed strategies

The preparation and for that reason the bonding of this sand mold are the essential action and really often are the rate-controlling action of this process. 2 main courses are utilized for bonding the sand molds: The "environment-friendly sand" includes combinations of sand, clay, and moisture. The "completely dry sand" contains sand and artificial binders treated thermally or chemically.

The Main Principles Of Premier Aluminum Llc

Mold making might be a specifically intricate art and is predicated on a comparable principle as gravity pass away casting illustrated in Figure 4. In the "reduced pressure" sand casting technique, the melted steel is compelled to get in the mold and mildew by reduced difference. This a lot more challenging procedure enables the assembly of cast products with thinner wall surface thickness.

There are ranges of die casting procedures, as we explained in this short article. High passes away spreading is that the most normally made use of, standing for about 50% of all light alloy casting manufacturing. Low-pressure die spreading presently represents about 20% of manufacturing and its use is boosting. Gravity dies casting represent the remainder, with the exception of a little however the expanding contribution from the recently presented vacuum dies spreading and capture casting procedure.

The majority of parts making up a classical mold and mildew for gravity pass away casting. Cores (inner components of the mold) are normally made from bound sand. Gravity dies spreading appropriates for manufacturing and for completely mechanized aluminum spreading. In this aluminum casting procedure, the fluid metal is infused at broadband and high into a metal mold with the assistance of die casting tools.

Premier Aluminum Llc - The Facts

One plate is taken care of and as a result the other can move in order that the die is typically opened up and closed. A gauged quantity of metal is poured into the shot sleeve after that introduced right into the mold dental caries using a hydraulically driven piston. As soon as the metal has actually solidified, the die is opened and consequently the spreading is gotten rid of.

The pressure inside the die is lowered by an air pump and for that reason the distinction of pressure forces the liquid metal to go into the die. This transfer is a smaller sized quantity rough than other spreading techniques so that gas inclusions are commonly really limited. Therefore, this brand-new strategy is especially intended towards components that will subsequently be heat-treated.

During the supreme phases of closure, the liquid is displaced right into the further components of the die (Aluminum Casting). Hence creating alloys, which usually have poor fluidness which normally avert the spreading route, are usually cast by this process.

Some Ideas on Premier Aluminum Llc You Should Know

Squeeze spreading pressures liquid aluminum to penetrate the preformed as compared to non-reinforced light weight aluminum alloy, light weight aluminum alloy matrix composites made by this system can double the exhaustion toughness at 300C. Such supports are frequently utilized at the sides of the piston head of a diesel where solicitations are especially high.

This article covers the primary usual elements that contribute to a selection on which method is the best one for you. Along a side a quick overview of every factor, we'll keep in mind which of the three processes meets that call for ideal: Sand Casting automated procedures, like at Dolin Casting Manufacturing, offers a high outcome of parts during a short quantity of your time in contrast to long-term mold processes.

(https://www.brownbook.net/business/53359936/premier-aluminum-llc/)Irreversible mold and mildew spreading supplies the very best material toughness within the completed product. Although almost like die casting, the items produced through permanent mold and mildew spreading have a plus throughout this area many thanks to the character of the approach. Sand Spreading provides the primary advantageous balance between higher quantities and tooling prices, while a permanent mold may be a better second.

Excitement About Premier Aluminum Llc

Report this page